- Phone: +91-9630011116

- Mon- Sat (10am - 7pm)

- info@inhibeo.com

Home / STP Plant Manufacturer

A sewage treatment plant (STP) is a facility that treats wastewater, which is typically sewage, with the goal of removing contaminants and preparing the water for reuse or release into the environment.

Such STP plants have the capacity to treat the sewage and this is done through a combination of biological process and chemical process coupled with mechanical process. Sewage Treatment Plants are the most important part of urban infrastructure, which maintains hygiene and the environment.

The quantity of sewage generated is growing at a high rate as urban populaces multiply. An efficiently operational sewage water treatment plant guarantees that with no treatment, the waste does not contribute to the pollution of our water bodies hence eliminating the chances of disease outbreaks and loss of natural resources.

Sewage recycling plants can recycle wastewater and thus such plants save water, which they need in arid areas.

Furthermore, a good sewage treatment plant promotes sustainable development by reducing water contamination and allowing for the reuse of treated water.

Sewage management can be traced to early civilization. STP plants have now advanced in with more technical aspects e.g. the Moving Bed Biofilm Reactor (MBBR) and Membrane Bioreactor (MBR).

This is a time when residential and commercial needs are addressed by a compact, efficient, all in one, package sewage treatment plant, developed by the innovations of sewage treatment plant manufacturers and the sewage treatment plant suppliers around the world.

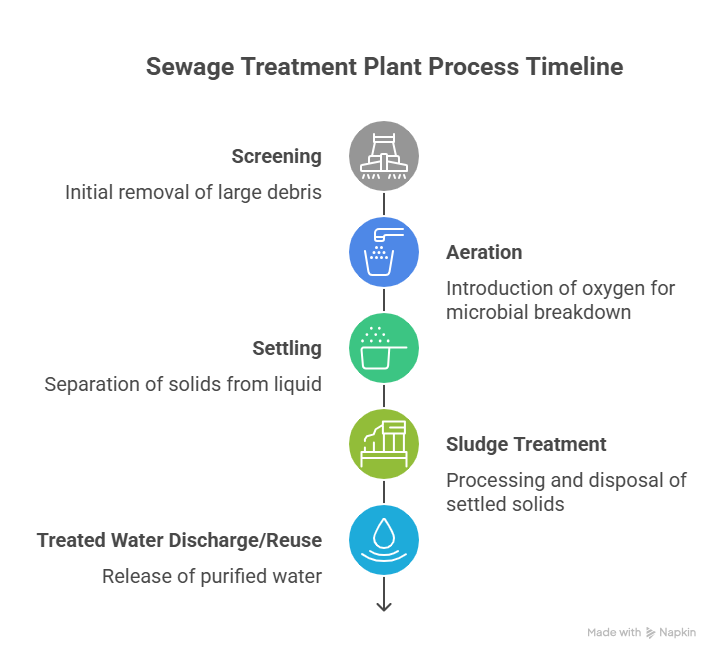

A typical sewage treatment plant process begins at screening, moves through aeration, settling, and ends with sludge treatment and treated water discharge or reuse. This sequence

STP plant is a combination of different systems:

ensures maximum removal of contaminants.

In the ASP system, the aeration tanks are utilized in which the organic matter is broken down by the microorganisms. It is popular among municipalities and has been characterized by efficiency and ease.

The sewage treatment plant uses MBBR where biofilm carriers are used in the aeration tank. Such carriers promote the growth of bacteria which helps to increase the level of biological treatment with the reduction of space.

SBR systems operate in cycles of filling, aeration, settling, and decantation. Such a form of sewage treatment plant is suitable to those of small to medium scale.

MBR technology combines the biological treatment method with the process of membrane filtration. It discharges clean effluent that is of good quality and can be recycled which has been a reason why it has been in demand especially in sewage recycling plants.

The wastewater in the RBC system is circulated over discs that rotate and their surface is covered with biofilm. It is energy efficient and it is utilized in decentralized configurations.

The system prolongs the aerating time so that there is improved decomposition of organic material. It works well in the treatment of sewage plants in small societies.

Compact Sewage Treatment Systems are packaged, prefabricated units designed for quick and easy installation. It was most suitable in residential complexes, hotels and offices

Screening Chambers

They filter out the big debris and solids coming into the sewage, which would damage other downstream devices.

Grit Removal Units

The other heavy particles such as sand and gravel are filtered in these units to avoid wear and clogging.

Aeration Tanks and Diffusers

Critical in biological methods of treatment, the source provides oxygen that aids in digestion of pollutants by microbes.

Settlers and Clarifiers

Settlement of solids treated water separation into clarifiers enables clarity of sludge.

Sludge Digesters

It was used to treat and also to reduce sludge volume by a biological digestion process.

Control Panels, Pumps, and Blowers

These parts secure the rightness of a wastewater stream and automation of the course of the plant.

Monitoring and Automation of IoT:

The use of IvT sensors and automation in training real-time monitoring of contents is employed in modern STP plants, making them more efficient and lessening the work done manually.

ZLD systems have zero effluence, a factor that fosters the sustainability of a system that recovers all water.

The maintenance requirements and equipment failures can be predicted using AI-powered STPs to minimize downtime and related expenses.

Biogas, Sludge-to-Energy Energy Recovery Technologies:

At some wastewater treatment plants, the sludge is used to recover energy by producing biogas or by generating electricity.

By using AI-powered STPs, the need to take equipment offline to ensure its movements in a dock is done systematically, and they can forecast failed parts and equipment maintenance, saving on downtime and costs.

Small STP plants provide a high level of Wastewater Treatment in residential localities.

Sewage treatment systems enable commercial property to comply with the applicable laws or regulations regarding the environment.

These plants require special sewage treatment plants to receive various and occasionally hazardous wastes.

Indeed, sewage treatment plants offer long-term solutions to congested campuses that consume a lot of water.

Industrial sectors produce wastewater with lots of strength that needs a strong method of treatment:

Municipal wastewater is collected and treated in large sewage treatment plants where the wastewater is cleaned to ensure the health of the people and water bodies.

STPs are used by transport hubs to sanitize, reuse water, and comply with the environment.

The new Sewage Treatment Plants (STPs) not only do the wastewater treatment but also provide a means of sewage recycling into numerous uses. The water reused after treatment in STP plants may safely be reused, putting less load on the freshwater resource.

Agricultural irrigation can take place using treated water in a sewage water treatment plant, thereby supplying nutrients that are needed by crops and cutting down use of chemical fertilizers.

In residential complexes, hotels, and community parks, sewage recycling plants provide landscaping and gardening water.

Treated sewage water is used in industries in the form of industrial cooling, thus assuring conservation of potable water and envisaging environmental regulations.

The treated wastewater is best suited for flushing toilets in both commercial and residential premises and in the construction sector in areas such as curing concrete and dust prevention.

Treated water recharge systems are put in place by Sewage Treatment Firms to recharge groundwater, hence helping in conserving water and making it sustainable.

The sewage treatment plants save water bodies from pollution, encourage the reuse of water, and stave off the transmission of waterborne illnesses. They promote balance in the ecosystem through clear effluence.

The challenges encountered in STP plants include control of odor, disposal of sludge in a safe manner, and energy expense despite their advantages. These problems can be resolved by means of advanced technologies, like Zero Liquid Discharge (ZLD) and energy recovery.

Effective producers of sewage treatment plants ensure that they construct systems that can reduce the carbon impact such that renewable energy is related to the systems and greenhouse gases are minimized using process optimization techniques.

Adequate planning will make the sewage treatment facility sensitive to the requirements of the individual users as well as the local environment.

Key components in this respect are size of inflow, quality of effluent, space requirements, and scalability in the future. An STP plant that is properly designed is long-term effective and compliant.

Capacity estimation is of the essence. Under-sizing means a system is overloaded; over-sizing adds too many capital costs. Manufacturers of STP plants provide professional sizing advice.

The sewage package treatment plants suit the small areas. Site selection should also be done properly so that there will be ease of operation and maintenance.

Cost and budget are essential to plan long-term efficiency and sustainability of a sewage treatment plant (STP). Cost can be of two categories:

The design, procurement, and installation of the STP plant (such as the use of pumps and aeration tanks and the control panel) constitute the capital cost. These costs also include civil constructions and commissioning.

Operational costs will be related to the cost of operations of the sewage treatment plant on a daily basis, i.e., consumption of energy, consumption of chemicals, labor, and maintenance. Complex processes are likely to increase the cost of operations of an industrial setup, including a wastewater treatment plant that is industrial.

Businesses have the option of using a package sewage treatment plant or a modular sewage treatment plant in order to save money. They are manufactured in pieces, so they take fewer hours to get installed and hardly any civil work.

Also, through associating with companies engaged in manufacturing Sewage Treatment Plants that have many years of experience, quality and economical installations can be provided.

Government incentives and subsidies are influenced by ever-present opportunities, which can be key factors in the forces of demand and supply on products and services. In India, government agencies offer subsidies for sewage recycling plants and zero liquid discharge systems to promote sustainable Wastewater Management, reducing capital investment significantly.

Modular STPs that are packaged in modules are suited to the small residential complex and business buildings. These systems are scalable as well as easy to maintain, and they provide a feasible solution with less space and cost.

Container sewage treatment plants are easily transported and fully integrated systems, which can be attached in remote or temporary applications. They are so efficient because of their small size and are easy to move.

Routine checks of equipment such as aeration tanks, pumps, and sludge digesters are required to operate most efficiently. System dependability is guaranteed by maintenance schedules that increase STP plant life.

Such problems as clogging, smell, or equipment failure may hinder operations. Quality sewage treatment companies offer troubleshooting and preventive maintenance services.

A competent workforce is essential in ensuring that there is smooth running and compliance with environmental standards. Lots of suppliers of sewage treatment plants provide operator training services and support.

STP plants should follow the specifications put forth by the Central Pollution Control Board (CPCB) and the State Pollution Control Boards (SPCB) to avoid penal charges.

It is illegal to have operations running without valid environmental clearance and certificates. There is smooth functioning with proper submission and compliance.

Failure to comply with the effluent discharge standards and standards may result in fines and legal proceedings, particularly in the case of industrial wastewater treatment plants.

The sludge is treated, which can be done through dewatering, composting, or incineration. They are some of the practices that are used in managing waste in Effluent Treatment Plants (ETP).

High technologies make it possible to convert the sludge into biogas or fertilizer, which is more sustainable and waste-reducing.

The automotive industry also produces oil-polluted wastewater, which necessitates special effluent works of sewerage.

The textile industries discharge dyed wastewater that requires substantial ETP plants or ZLD systems provided by the leading manufacturers of ZLD plants.

Hotels require small and nonstinking remedies. Compact STPs and packaged effluent treatment plants are common.

Hospitals have to ensure enhanced treatment of wastewater to treat the biomedical and pharmaceutical wastes, and hospitals normally combine multi-effect evaporators (MEE) or mechanical evaporators.

By using technologies from top MEE Evaporator Manufacturers and ZLD system providers, industries can meet compliance and sustainability goals effectively.

Strong sewage treatment plants (STPs) are crucial for developing wastewater management systems, safeguarding public health, saving water, and adhering to regulations. They serve long-term development and environmental management in urban and industrial areas. Cooperation with other manufacturers and suppliers ensures high quality, efficiency, and regulation of wastewater systems based on individual industry requirements.

India also has quite a number of major sewage treatment plant (STP) manufacturers that have taken it upon themselves to design an efficient and sustainable sewage water treatment plant. These companies provide custom products to the residential, commercial, and industrial sectors and also ensure that the products are environmentally friendly to the local regulations.

By going with suppliers of local sewage treatment plants, it is possible to have quicker delivery; they are less expensive and easier to support maintenance and service. Septic treatment firms in the area are also used to meeting local standards and can do fast troubleshooting and spares. Their features also assist in making changes to the design of the STP plant in accordance with certain climatic and geographic conditions.

Qualified STP plant manufacturers have certifications like ISO 9001 and ISO 14001, and they are CPCB and SPCB compliant. It is necessary to confirm the certification of the suppliers of the wastewater treatment plant to guarantee the quality of the product, its performance, and its durability.

As a manufacturer of sewage treatment plants, it is necessary to consider the experience of the manufacturer to build industrial wastewater treatment plants or package sewage treatment plants. Seek manufacturers that are providing the latest technology, such as Zero Liquid Discharge (ZLD) and Multi-Effect Evaporators (MEE), with strong after-sales support and technical assistance.

A complete Annual Maintenance Contract (AMC) provides a long-time safe run of the STP plant. The top sewage treatment plant manufacturers have quick after-sales services, regular caretaking, and emergency provision.

It is good to take into consideration the price, but what should matter is long-run value and efficiency. Better materials, validated technology, and efficient energy devices reduce work expenses while increasing system dependability over time.

IoT sensors are becoming involved in modern Sewage Treatment Plants and undergo monitoring with the use of AI and automation. Such intelligent systems make it possible to even track parameters in real time, perform predictive maintenance, and optimize energy use, minimizing downtime and leading to increased efficiency of treatment.

Green sewage treatment plants use alternative sources of energy that are renewable as operating energy sources, like biogas or solar panels. The method is a sustainable procedure that reduces the environmental effect and operating costs of sewage water treatment plants.

Decentralized compact sewage recycling plants are in demand. It fits well in small communities, in rural places, and in the industries and has the benefit of being locally treated without requiring elaborate infrastructure coverage.

Successful STP installation requires proper selection of sites. It should be a place where access is easy and where the components, such as grit removal units, aeration tanks, and sludge digesters, can be organized optimally and with regard to local codes.

Effective planning and coordination with competent manufacturers of sewage treatment plants can help in the flow of the construction process. Package sewage treatment plants are prefabricated and cut down on the installation time to a large extent.

STP installation is the main concern of safety. Observe the equipment handling guidelines, the electrical safety procedures, and the confined space entry. Do business with certified companies in wastewater treatment that insist on safety measures.

Sewage treatment plants (STPs) play a crucial role in sustainability, conformity, and cost-saving. STPs are used in the colored industrial effluent processes in the textile industry, where it becomes possible to reuse the water. All the wastewater of the pharmaceutical industries is reprocessed through Zero Liquid Discharge (ZLD) systems.

Effluent treatment plants (ETPs) and industrial wastewater treatment plants minimize the use of water and expenditures in the automobile industry.

An example is a multi-effect evaporator (MEE) industrial wastewater treatment plant in Gujarat, which aims at reusing 90 percent of water. In another project in Pune, there was a project to put in a packaged sewage treatment plant within a residential township that enables the reuse of treated water in landscaping and flushing.

Prior to STP implementation, industries faced water shortages, fines, and health hazards due to untreated sewage. Recycling plants have since been installed, allowing treated sewage water for cooling, gardening, and other purposes.

A hotel chain invested in a small Effluent Treatment Plant, saving 40% of water expenses and complying with CPCB/SPCB. Municipalities with wastewater treatment plants experienced improved public health and reduced waterborne diseases.

Reliable providers of sewage treatment plants and technology can have a considerable impact on effective wastewater treatment methods.